Sleeving

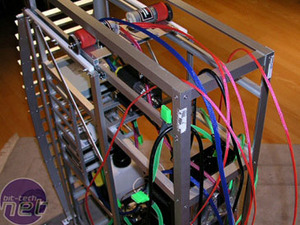

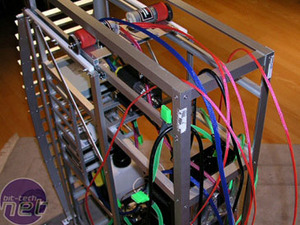

With most of the electronics mounted I decided to start sleeving all the cables; nearly 40m of different sleeving and 80 UV-active connectors later:

...week after week... sleeve, solder, sleeve, solder...

The result of all my hard work?

24 UV-active CCFL's - this 'show' effect is one of the most important details in this project, if light does catch your eye what will?

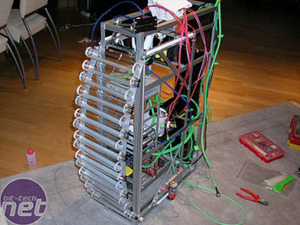

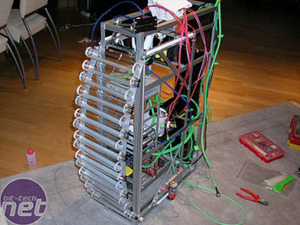

The water tubes

A few pictures ago you got a brief preview of the water tubes which will adorn the front of the case, let's have a look at them in a little more detail.

A friend of mine is a professional plastic designer; he's an expert at cutting/milling plexiglass, plastic and thin metal. I ordered forty caps for the standard water tubes and used 'Roehm' superglue to attach the ends to the tubes. The pictures above show my testing of the tubes to make sure they're waterproof.

I used plug connectors for the water tubes, a special combi drill/tap was used to but the thread for them, most of them I did by hand. All lined up...

Silicon glue was used to fix the tubes to the bars on the front of the case; it smells bad for the first day or so but it's the best way to mount plastic on metal in this case as it needs to be flexible, I don't want anything to break is the front of the case is blocked in any way:

With most of the electronics mounted I decided to start sleeving all the cables; nearly 40m of different sleeving and 80 UV-active connectors later:

...week after week... sleeve, solder, sleeve, solder...

The result of all my hard work?

24 UV-active CCFL's - this 'show' effect is one of the most important details in this project, if light does catch your eye what will?

The water tubes

A few pictures ago you got a brief preview of the water tubes which will adorn the front of the case, let's have a look at them in a little more detail.

A friend of mine is a professional plastic designer; he's an expert at cutting/milling plexiglass, plastic and thin metal. I ordered forty caps for the standard water tubes and used 'Roehm' superglue to attach the ends to the tubes. The pictures above show my testing of the tubes to make sure they're waterproof.

I used plug connectors for the water tubes, a special combi drill/tap was used to but the thread for them, most of them I did by hand. All lined up...

Silicon glue was used to fix the tubes to the bars on the front of the case; it smells bad for the first day or so but it's the best way to mount plastic on metal in this case as it needs to be flexible, I don't want anything to break is the front of the case is blocked in any way:

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.